The technical side of Azoterra and Luxaterra louvre roofs: how do they really work?

Louvre roofs, particularly those designed by Azoterra and Luxaterra, are becoming increasingly popular in the construction industry due to their unique and visually appealing aesthetics. But beyond their captivating appearance, these roof systems have a complex and elaborate technical side that often remains unknown to the general public.

How do these roofs really work? What underlying mechanisms enable their remarkable structural stability and burden-sharing?

In this discussion, we will look at the technical aspects of louvre roofs and uncover the secrets behind their design, installation process and overall functionality. By exploring the inner workings of these architectural masterpieces, we aim to shed light on the engineering genius behind their stunning facades.

Louvre roof systems: An overview

Louvre roof systems offer a structured and efficient solution for covering large areas and provide a comprehensive overview of their design, installation and benefits. These systems consist of lightweight, prefabricated components arranged in a series of parallel layers to form a series of triangular or trapezoidal shapes. The individual slats or blades are usually made of steel or wood and are designed to be self-supporting.

The design of louvered roof systems enables efficient load distribution, as the weight of the roof is evenly distributed over the individual blades. This structural arrangement results in a high degree of strength and stability, which makes it possible to build large, open spaces without additional supporting structures. In addition, the triangular or trapezoidal shape of the slats ensures natural drainage and eliminates the need for complex drainage systems.

The installation of louvre roof systems is relatively straightforward, as the prefabricated components can be quickly and easily assembled on site. This reduces construction time and costs and makes louvre roofs a cost-effective option for covering large areas.

The advantages of louvre roof systems go beyond their structural and installation-related benefits. The design allows sufficient natural light to pass through, reducing the need for artificial lighting during the day. In addition, the open design of these roofs promotes natural ventilation, which improves the comfort and well-being of the residents.

Structural design and components

The structural design and components of louvered roof systems play a decisive role in efficient load distribution and overall stability. Louvred roofs consist of a frame of interconnected beams, known as louvres, which form a grid-like structure. These slats are usually made of high-strength materials such as steel or wood, which are selected for their ability to withstand the forces exerted on the roof.

The design of the slats is carefully calculated to achieve optimum load distribution. The dimensions and spacing of the beams are determined based on factors such as the roof span, the expected loads and the desired aesthetic appearance. By distributing the loads evenly across the structure, louvre roofs can carry heavy loads such as snow or wind without compromising their stability.

In addition to the slats, louvre roof systems also include other components that contribute to structural integrity. These can include connecting elements such as bolts or weld seams that join the slats together, as well as support elements such as columns or trusses that provide additional stability. The connections between the slats and other components are carefully designed to ensure proper load transfer and avoid weak points in the structure.

Load distribution and stability

Efficient load distribution and overall stability are decisive factors for the successful operation of slatted roof systems. Louvered roofs are designed to handle various types of loads, including dead weight loads such as the weight of the roof structure itself, as well as live loads such as snow, wind and loads from equipment. Load distribution in slatted roofs is achieved by arranging several individual slats that work together to distribute the loads evenly over the entire roof structure.

The stability of slatted roof systems is guaranteed by careful planning and construction. The individual slats are strategically placed and joined together to create a rigid and stable structure. The geometry and alignment of the slats play a decisive role in improving the stability of the roof system. The inclined alignment of the slats helps to distribute the loads and forces more efficiently and minimize the risk of structural failure.

In addition, the connection points between the slats and other components are designed to provide sufficient strength and stability. These connection points are carefully analyzed to ensure that they can withstand the loads and forces exerted on the roof system.

Assembly process and installation methods

During the installation process of louvre roof systems, precise installation procedures are used to ensure structural integrity and optimum performance. The installation process begins with careful preparation of the construction site, including leveling and correct alignment of the supporting structure. This ensures that the slatted panels can be installed accurately and safely.

The installation of the slatted panels requires careful attention to detail. Each panel is carefully positioned and connected to the supporting structure using special fasteners and joints. These fasteners are designed to provide a strong and secure connection while allowing for expansion and contraction of the louvre panels due to temperature changes.

Once the panels are in place, the next step is correct alignment and spacing. This is crucial for an aesthetically pleasing and functional louvre roof. Precise measurements are taken to ensure that the panels are evenly spaced and aligned to maintain the desired aesthetic appeal and ensure efficient rainwater drainage.

In addition, the installation of slatted roofs often requires the use of special equipment and tools. This includes cranes or elevators to safely handle and position the slatted panels, as well as precise measuring instruments to ensure accurate placement and alignment.

Performance and durability factors

To ensure the long-term performance and durability of slatted roof systems, several key factors must be considered and carefully implemented during the assembly and installation process. These factors include the selection of high-quality materials, appropriate design and construction and a careful installation method.

One of the main factors contributing to the performance and durability of louvre roofs is the choice of materials. It is important to use materials that are resistant to weathering, corrosion and UV radiation. For example, using high-quality aluminum or stainless steel for the slat blades can prevent rusting and deterioration over time. In addition, selecting a sturdy and durable frame, such as galvanized steel or aluminum extrusions, can improve the overall structural integrity of the system.

Appropriate design and construction play an important role in the long-term performance of slatted roofs. The design should take into account factors such as wind loads, snow loads and thermal expansion and contraction. By precisely calculating these loads and incorporating them into the design, the system can withstand external forces and maintain its structural integrity.

Accurate execution is crucial during the installation process. Each blade should be installed securely, with correct alignment and spacing to ensure optimum performance. The connections between the lamella blades and the supporting structure should be carefully designed to avoid weak points or potential failure points.

Regular inspections and maintenance work are also important for the performance and durability of louvre roofs. Routine inspections can identify signs of wear, damage or potential problems so that repairs or replacements can be carried out in good time. In addition, keeping the system clean of dirt and regularly lubricating moving parts can prevent premature wear.

Advantages and applications of louvre roofs

Louvre roofs offer numerous advantages and have a variety of applications in different industries and architectural designs.

One of the main advantages of louvre roofs is their ability to provide a lightweight but structurally strong roofing solution. By using lightweight materials such as steel or aluminum in combination with the unique design of the slats, the overall weight of the roof can be reduced while maintaining its strength and durability.

Another advantage of louvre roofs is their design flexibility. The individual slats can be adjusted in terms of their size, angle and spacing, allowing a high degree of architectural freedom. This design flexibility makes it possible to integrate louvre roofs into different architectural styles, from modern and contemporary to traditional and historic.

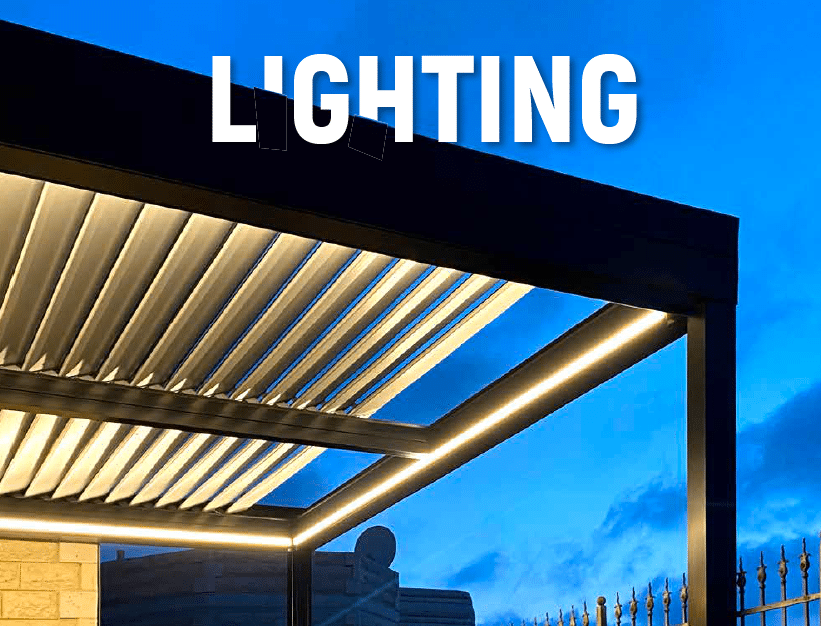

Louvred roofs also offer excellent natural ventilation and daylight options. The open spaces between the slats allow air to pass through and promote airflow, reducing the need for mechanical ventilation systems. In addition, the sloped louvres can be designed to optimize the entry of natural light into the building, reducing the need for artificial lighting during the day and improving energy efficiency.

In terms of applications, louvre roofs are often used in stadiums, exhibition halls and large public spaces where wide spans and open spaces are required. They can also be found in industrial buildings, warehouses and agricultural buildings, where their lightweight and durable nature is ideal for covering large areas. In addition, louvre roofs are increasingly being used in residential and commercial buildings to create unique and visually appealing architectural designs.

Conclusion

In summary, louvre roofs such as Azoterra and Luxaterra are an innovative roof system that offers numerous advantages in terms of design flexibility, load distribution and durability.

Through a carefully designed structure and assembly process, these roofs provide stability and performance in various applications.

Their unique components and installation methods contribute to their effectiveness and long-term functionality.

Overall, louvre roofs are a promising solution for efficient and sustainable roof systems in the construction industry.